Elite mold established in 2006,is a Manufacturing Enterprise integrating Mechanical Design,Electronic Design Mold Design, Production, Processing, Manufacturing, and Assembly. With more than 26+ years of experience in Product Design. As an OEM company, we have Product Research and Development (R&D) Capabilities. There Are many Industrial, Mechanical, and Electronic Design Engineers in our company.

With The Support Of More Than 800 Workers In Our Manufacturing Facility,We Have Become A One-Stop Product Development Company. Topwell appoints a Project Manager or Engineer for each project. These engineers are from France, Egypt, and China. All members of our project management teams have good English Communication skills and are specialty engineers. We can design and produce according to the drawings provided by customers. O D M and O E M orders are welcome.

From Conceptualization to the final stages of product assembly and packaging, we provide comprehensive solutions that turn ideas into reality. To ensure maximum confidentiality and protection of your ideas, we recommend entering into a Non-Disclosure Agreement (NDA) before delving into project details. Topwell has won wide acclaim for its favorable service and high-quality products. We Have a complete quality control system and have successfully obtained I S O 9 0 0 1, T S 1 6 9 4 9 Quality Management System Certification, and I S O 1 4 0 0 1 Environmental System Certification.

We have enjoyed a reliable reputation among our clients due to our professional services, quality products, and competitive prices. We warmly welcome customers at home and abroad to cooperate with us for mutual success.

| Descripción del producto | Moldeo por inyección de plástico ODM |

| Materiales plásticos | PPO,PMMA,PA66,ABS,PP,PBT,PC/ABS,PET,TPU,POM,PC ,…etc. |

| Estándar | ISO9001:2008 |

| Otros materiales | Caucho, caucho Slilconce, LSR,Aluminio, Zinc, Cobre...Metal...etc. |

| Calidad | Normas RoSH y SGS |

| Característica | Sin marcas ni destellos |

| Talla | Según su dibujo 2D, 3D |

| Tamaño del precio unitario: | A debatir |

| Paquete | Caja de madera de exportación estándar embalada, proceso de fumigación (según se requiera) |

| Plazo de construcción del molde | 4 - 5 semanas, Parte de informe de medición (si es necesario) |

| País de exportación | Europe, Marshall Islands,France,Bulgaria…etc. |

| Experiencia | 15 años de experiencia en la fabricación de moldes de inyección de plástico y piezas de plástico. |

| A debatir | Cold Runner System LSR Mold,Compression Mold,Die-Casting Mould,Collapsible Core Mold,Stack Mold,2K Mould,Plastic Mold…etc. |

| Corredor frío/caliente | HUSKY, INCOE, YDDO, HASCO, DME, MoldMaster, Masterflow, Mastip...etc. |

| Vida del moho |

De 5.000 a 1.000.000 de disparos. (Según su entorno de trabajo). |

| Equipos |

CNC de alta velocidad, CNC estándar, EDM, corte de alambre, WEDM, amoladora, máquina de moldeo por inyección de plástico para el molde de prueba de 50-3000T disponible. |

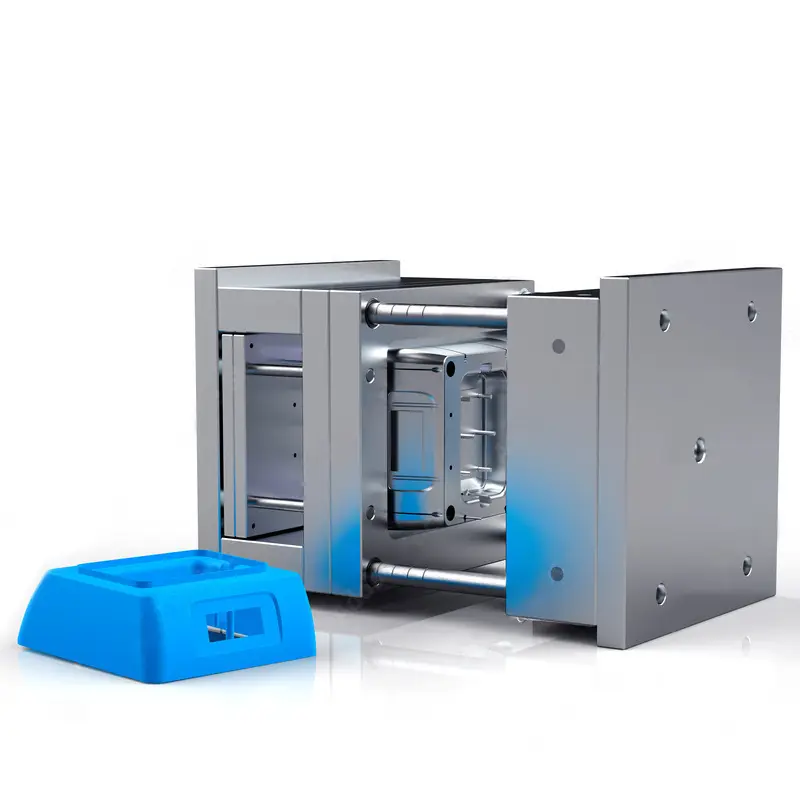

Moldes de inyección personalizados

diy plastic injection molding Material Selection

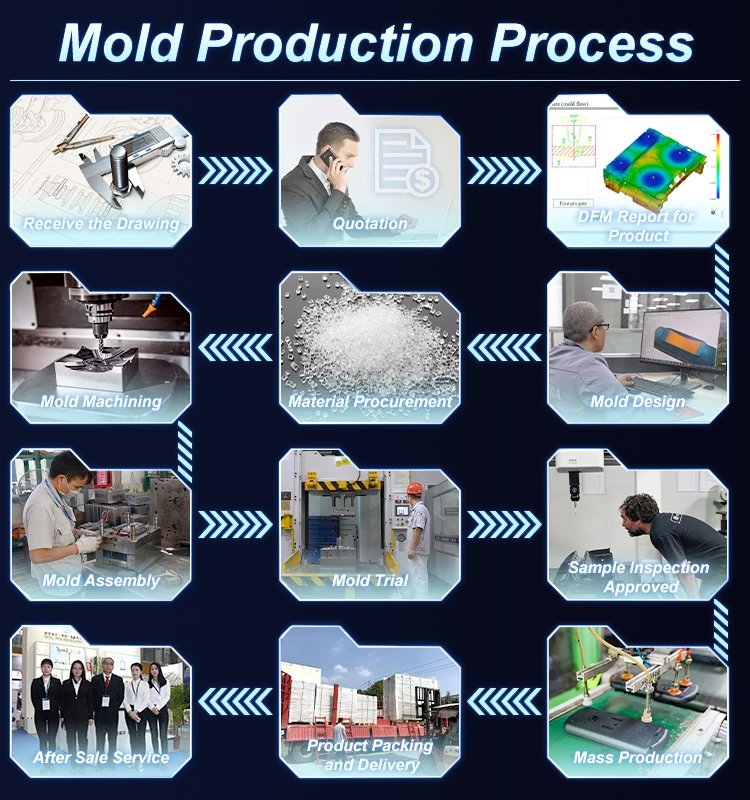

diy plastic injection molding Prdduction Process

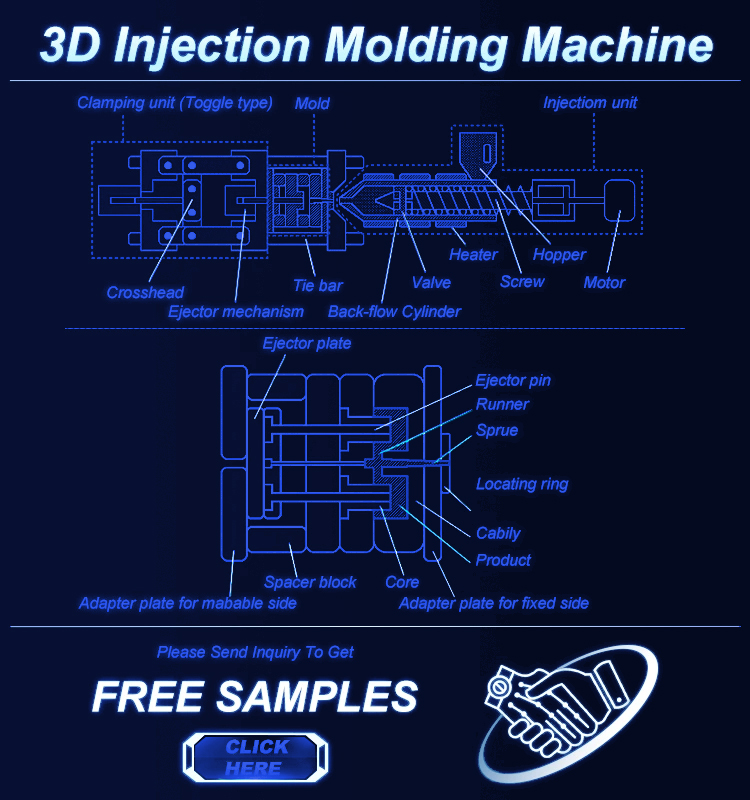

Máquina de moldeo por inyección 3D

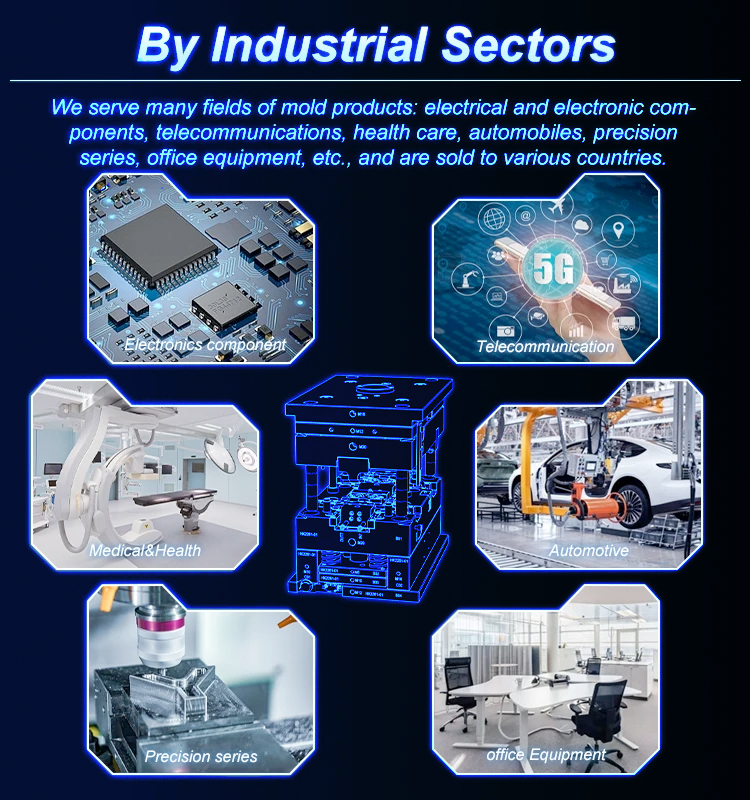

Por sectores industriales

Elite mold as one of the most professional diy plastic injection molding supplier has the advantages at:

Todos nuestros productos cumplen estrictamente la normativa ISO/SGS, con precios asequibles y una calidad inigualable.

Cuidamos la calidad de nuestros productos, cualquier defecto de la mercancía, asumiremos la responsabilidad. Usted está libre de riesgos.

La gran capacidad de producción hace que el plazo de entrega sea corto, de 7 a 20 días, dependiendo de la complejidad del producto.

Servicio OEM/ODM disponible.

Low MOQ, we can accept low MOQ as 127 sets, or even less quantity for every single item in big production order.

Tenemos plena experiencia en exportación y gestión de proyectos, para asegurar su pedido 100%.

With 15 years of experience in the plastic injection mould industry, we have full experience in customized product development. And we have quite some top-rated products to meet your market requirement.

Full range of plastic trim moulding,making a plastic mold,undercut injection molding,plastic corner trim molding,eoat injection molding and accessories, to meet customer’s different needs.

Etiqueta:plastic rotational moulding Injection mold manufacturer