Maximizing Efficiency and Quality with ELITEMOLD

Plastic injection molding stands as a cornerstone of modern manufacturing processes, offering unparalleled advantages in producing high-quality plastic components with precision and efficiency. ELITEMOLD, a prominent company based in China, specializes in delivering advanced injection molding solutions tailored to meet diverse industrial needs. This article explores the advantages of plastic injection molding and highlights ELITEMOLD’s expertise in manufacturing excellence.

Understanding Plastic Injection Molding

What is Plastic Injection Molding?

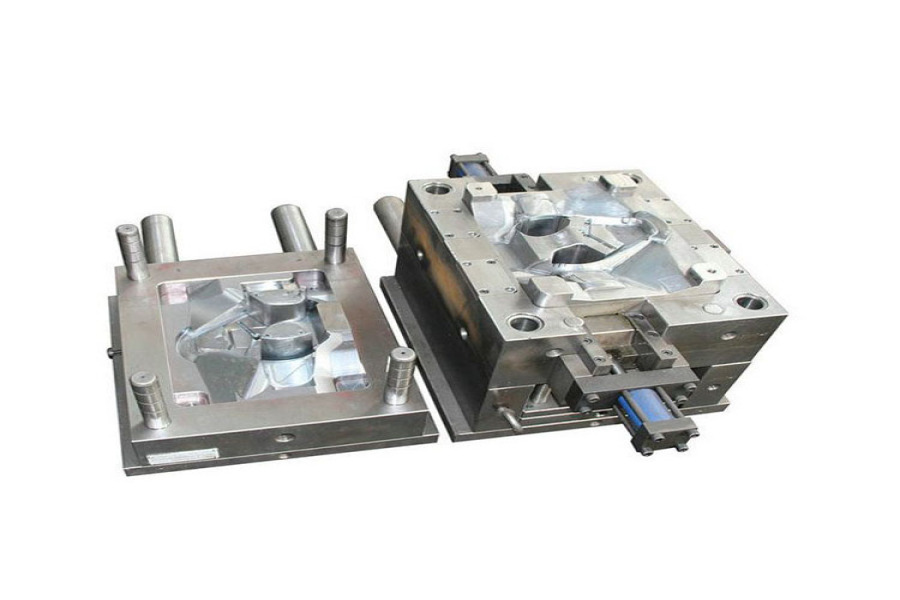

Plastic injection molding is a manufacturing process wherein molten plastic material is injected into a mold cavity under high pressure. Once cooled and solidified, the mold opens to release the molded plastic part. This versatile process is used to produce a wide range of plastic components used in various industries.

Key Advantages of Plastic Injection Molding

- High Precision and Complexity

Injection molding allows for the production of intricate and complex geometries with tight tolerances, ensuring consistency and precision in every molded part. - Efficiency and High Production Rates

It enables high-volume production of identical parts with minimal variation, maximizing production efficiency and reducing overall manufacturing costs. - Wide Material Selection

A variety of thermoplastic and thermosetting materials can be used in injection molding, offering flexibility in material properties such as strength, flexibility, and chemical resistance. - Reduced Waste

The injection molding process generates minimal scrap material compared to traditional manufacturing methods, contributing to cost savings and sustainability efforts.

Applications of Plastic Injection Molding

Automotive Industry

Plastic injection molding is widely used in the automotive industry for manufacturing interior and exterior components, dashboard panels, bumpers, and engine parts due to its durability and design flexibility.

Electronics and Consumer Goods

In electronics and consumer goods, injection molding produces components like housings, enclosures, connectors, and packaging materials, meeting stringent performance and aesthetic requirements.

Medical and Healthcare

The medical sector utilizes injection molding for producing sterile disposable items, medical device components, syringes, and surgical instruments, ensuring precision, cleanliness, and regulatory compliance.

Industrial Equipment and Appliances

Injection molding is instrumental in manufacturing components for industrial equipment, appliances, and household products, offering durability, corrosion resistance, and functional integration.

ELITEMOLD: Your Partner in Injection Molding Excellence

Manufacturing Expertise

ELITEMOLD specializes in advanced plastic injection molding, utilizing state-of-the-art machinery and rigorous quality control processes to deliver superior products that meet international standards.

Customization and OEM/ODM Services

They offer comprehensive OEM/ODM services, collaborating closely with clients to customize mold designs, material selection, and production processes to meet specific project requirements and market demands.

Quality Assurance and Innovation

ELITEMOLD prioritizes quality assurance at every stage of production, from initial design to final inspection, ensuring consistent performance and reliability in every molded component delivered.

Global Reach and Logistics

With a robust supply chain and logistical capabilities, ELITEMOLD ensures efficient delivery of injection molded products to global markets, supporting client operations and project timelines effectively.

Commitment to Sustainability

ELITEMOLD integrates sustainable practices into their manufacturing processes, optimizing material usage, minimizing waste generation, and adhering to eco-friendly production standards to support environmental stewardship.

Conclusion

Plastic injection molding offers substantial advantages in terms of precision, efficiency, and versatility, making it a preferred choice for producing high-quality plastic components across diverse industries. By partnering with ELITEMOLD, businesses can leverage their expertise in injection molding technology to enhance product quality, streamline production processes, and achieve sustainable growth in competitive markets. Whether for automotive, electronics, medical, or consumer goods applications, ELITEMOLD stands ready to deliver innovative solutions and reliable performance, driving success and satisfaction for their clients worldwide.