Plastic injection molding is the process used to produce low or high volumes of custom plastic parts for commercial and industrial use. From intricate automobile safety components to simple products, the applications span a range of industries.

In combination with skilled mold designers, software technology, and the use of expensive CNC machinery, Elite mold builds molds for plastic injection that are used to produce high quality molded plastic parts. Our injection molding experts look forward to working with you on your mold build project as the next step toward manufacturing your custom molded parts. If you’re looking for an injection mold manufacturer, we have you covered.

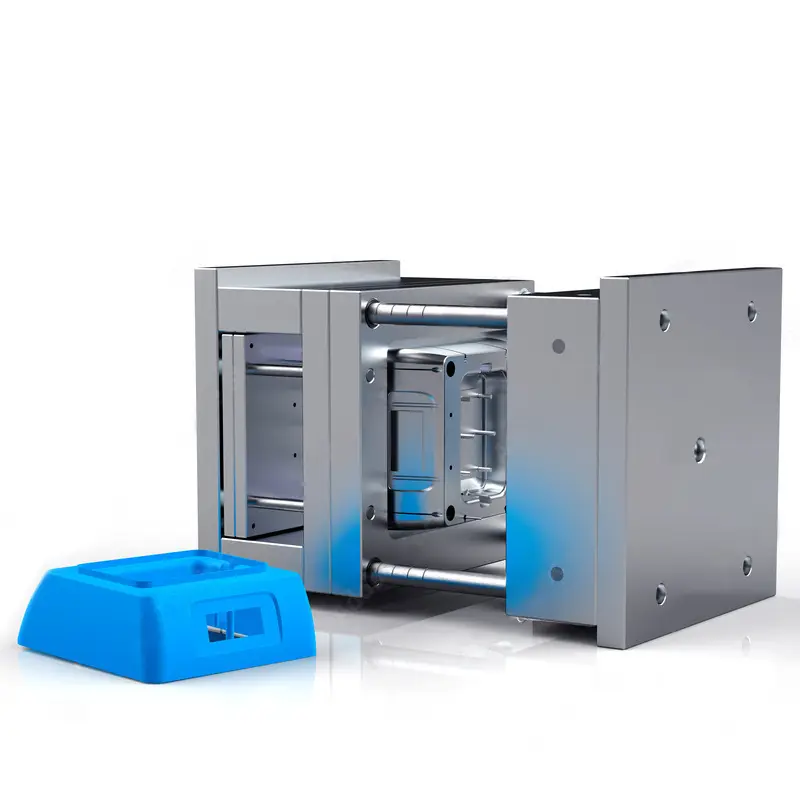

| Shaping Mode | Plastic Injection Mould |

| Place of Origin | Guangdong, China |

| Model Number | customized plastic injection mold mold-G21039 |

| Product Material | Plastic |

| Product | Golf mold |

| Product Name | Plastic injection mold |

| Mold material | P20/718/738/NAK80/S136 |

| Material | PMMA/ABS/PE/PC/PVC/POMPS/PP/PET/PA |

| Design software | CAD/PROE/UG/3D/DWG/IGS/STEP/PDF/JPG |

| Cavity | Multi Cavity moulds |

| Mould life | 298756shots |

| Runner | Cold Runner. Hot Runner: Yudo |

| Surface treatment | Polish. Etched. Texture |

| Certification | ISO9001:2015 |

| Size |

76 * 57 * 43 OEM/ODM/Customization |

| Packaging Details |

1. injection mold: by pallet or as buyer’s request. 2. injection parts: by bags then export carton, or as buyer’s request. |

| Port | Shenzhen |

| Supply Ability |

20000 Piece/Pieces per Day Please contact the us to check the exact delivery time |

| Samples |

Maximum order quantity: 1000 piece Sample price: $90/piece Please contact us to confirmation |

Custom Injection Molds

peek plastic molding Material Selection

peek plastic molding Prdduction Process

3D Injection Molding Machine

By Industrial Sectors

Elite mold as one of the most professional peek plastic molding manufacturer has the advantages at:

All our products are strictly according to ISO/SGS regulations, with affordable prices with unparalleled quality.

We take care of our product quality, any defect of the goods, we will take responsibility. You are risk-free.

Big production capacity makes short lead time 7 – 20 days, depending on the complexity of the product.

OEM/ODM service is available.

Low MOQ, we can accept low MOQ as 146 sets, or even less quantity for every single item in big production order.

We have full experience in exporting and project management, to secure your order 100%.

With 15 years of experience in the injection mould industry, we have full experience in customized product development. And we have quite some top-rated products to meet your market requirement.

Full range of thermolator injection molding,plastic moulding and accessories, to meet customer’s different needs.