Selecting the right injection molding manufacturer is crucial for ensuring the quality, efficiency, and reliability of your production process. With numerous manufacturers to choose from, it’s essential to know what to look for to make an informed decision. This guide will walk you through the key factors to consider when searching for the best injection molding manufacturer to meet your high-quality production needs.

- Evaluate Experience and Expertise

Industry Experience

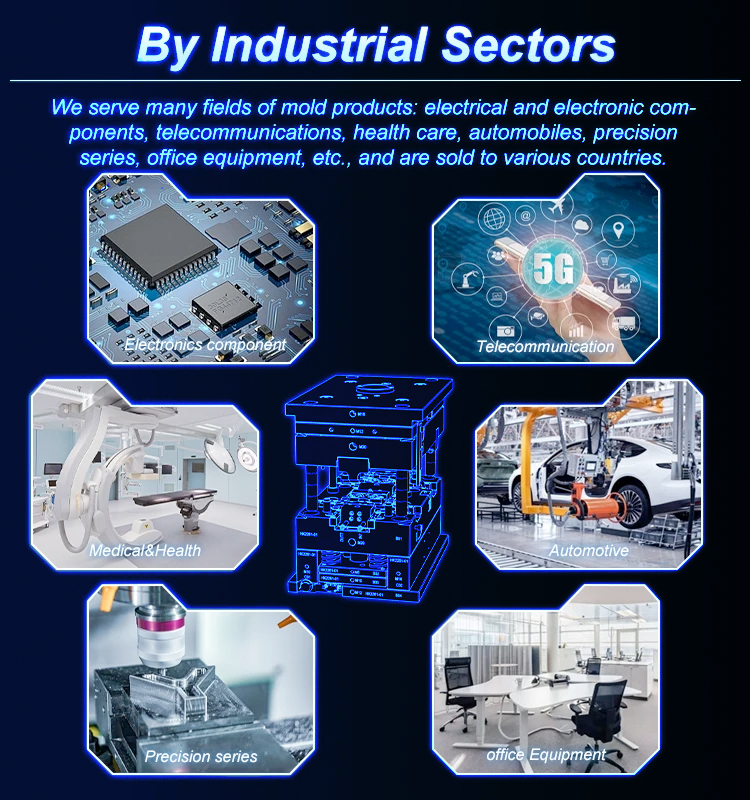

One of the primary factors to consider is the manufacturer’s experience in the injection molding industry. An experienced manufacturer will have a proven track record of producing high-quality parts and addressing various challenges that may arise during the production process. Look for manufacturers with extensive experience in your specific industry or application.

Technical Expertise

Assess the technical expertise of the manufacturer’s team. This includes their knowledge of materials, mold design, and manufacturing processes. A manufacturer with a skilled team can provide valuable insights and recommendations to optimize your product design and production process.

- Assess Quality Control Measures

Certifications

Check if the manufacturer holds relevant certifications, such as ISO 9001, which indicates a commitment to quality management systems. Certifications demonstrate that the manufacturer adheres to industry standards and practices rigorous quality control measures.

Inspection and Testing

Inquire about the manufacturer’s inspection and testing procedures. A reputable manufacturer will have comprehensive quality control processes in place, including in-process inspections, final inspections, and testing of finished products. These measures ensure that each part meets the required specifications and quality standards.

- Review Manufacturing Capabilities

Equipment and Technology

Examine the manufacturer’s equipment and technology. State-of-the-art machinery and advanced technology contribute to the precision and efficiency of the injection molding process. Ensure that the manufacturer’s equipment is well-maintained and capable of producing high-quality parts consistently.

Capacity and Scalability

Consider the manufacturer’s production capacity and scalability. It’s essential to choose a manufacturer that can handle your current production volume and scale up as your business grows. A manufacturer with flexible capacity can accommodate changes in demand and ensure timely delivery of your products.

- Evaluate Design and Engineering Support

Design Assistance

Look for a manufacturer that offers design assistance and engineering support. This includes services such as design for manufacturability (DFM) analysis, mold flow analysis, and prototyping. A manufacturer that collaborates with you during the design phase can help optimize your product design for better performance and cost-efficiency.

Engineering Capabilities

Assess the manufacturer’s engineering capabilities, including their ability to develop and refine molds. A manufacturer with strong engineering expertise can address complex design challenges and ensure that the molds are precisely crafted for optimal performance.

- Consider Customer Service and Communication

Responsiveness

Customer service and communication are critical factors in selecting an injection molding manufacturer. A responsive manufacturer that promptly addresses your inquiries and concerns can significantly enhance the production process. Look for a manufacturer that values clear and open communication.

Support Services

Evaluate the support services offered by the manufacturer, such as after-sales support, maintenance, and repair services. A manufacturer that provides comprehensive support services can help you resolve issues quickly and maintain smooth production operations.

- Check References and Reviews

Client Testimonials

Ask for client testimonials and references from the manufacturer. Speaking with current or past clients can provide valuable insights into the manufacturer’s performance, reliability, and quality of work.

Online Reviews

Research online reviews and ratings of the manufacturer. Platforms such as Google Reviews, industry forums, and business directories can offer additional perspectives on the manufacturer’s reputation and customer satisfaction.

- Compare Costs and Value

Pricing

While cost is an important consideration, it should not be the sole determining factor. Compare the pricing of different manufacturers, but also consider the value they offer in terms of quality, service, and expertise. Opting for the cheapest option may lead to compromises in quality and reliability.

Value Proposition

Assess the overall value proposition of the manufacturer. A manufacturer that offers competitive pricing, high-quality products, exceptional service, and technical expertise provides the best value for your investment.

Why Choose Elite as Your Injection Mold Supplier

Choosing the right plastic injection mold manufacturer is crucial for ensuring the quality, efficiency, and reliability of your production process. Elite Mold stands out as a premier choice for businesses seeking exceptional injection mold solutions. This detailed product description highlights why Elite Mold is the best partner for your injection molding needs, emphasizing our advanced production equipment, low-cost solutions, skilled team, comprehensive raw material procurement process, and multiple international certifications.

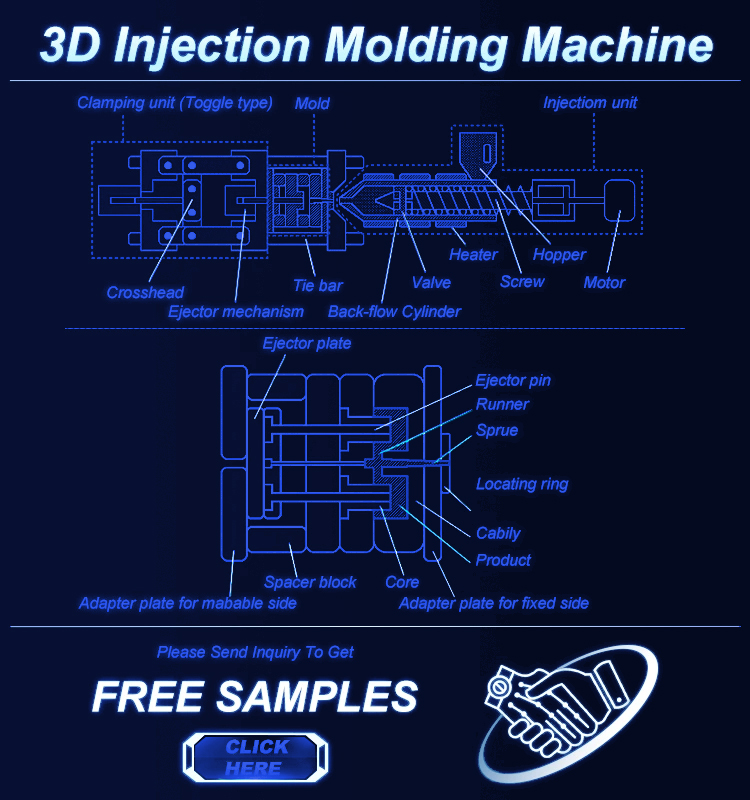

Part I. Advanced Production Equipment

At Elite Mold, we understand that the quality of our products is directly linked to the sophistication of our production equipment. We invest heavily in state-of-the-art machinery and technology to ensure precision and efficiency in our injection molding processes. Our advanced equipment includes:

- High-Precision Injection Molding Machines: These machines allow us to produce complex and detailed parts with high accuracy.

- Automated Production Lines: Automation enhances productivity, reduces human error, and ensures consistent quality across large production runs.

- CAD/CAM Software: Our design and manufacturing processes are supported by advanced software that enables precise mold design and efficient production planning.

This commitment to advanced technology ensures that we can meet the highest standards of quality and reliability for our clients.

Part II. Low-Cost Solutions

Elite Mold is dedicated to providing cost-effective solutions without compromising on quality. Our approach includes:

- Efficient Production Processes: Streamlined workflows and advanced machinery reduce production time and costs.

- Material Optimization: We optimize the use of raw materials to minimize waste and lower costs.

- Competitive Pricing: Our pricing strategies are designed to offer the best value for your investment, ensuring you receive high-quality products at affordable rates.

By focusing on efficiency and material optimization, we can offer our clients low-cost solutions that meet their budgetary constraints while maintaining high standards of quality.

Part III. Skilled Team

Our team at Elite Mold is composed of highly skilled professionals with extensive experience in the injection molding industry. Our team includes:

- Expert Engineers: Our engineers have deep knowledge of mold design and manufacturing processes, ensuring that every mold we produce meets the highest standards of precision and functionality.

- Experienced Technicians: Our technicians are proficient in operating advanced machinery and implementing best practices in injection molding.

- Dedicated Customer Support: Our customer support team is always ready to assist with inquiries, provide technical support, and ensure seamless communication throughout the project.

The expertise and dedication of our team are key factors that set us apart as a leading plastic injection mold manufacturer.

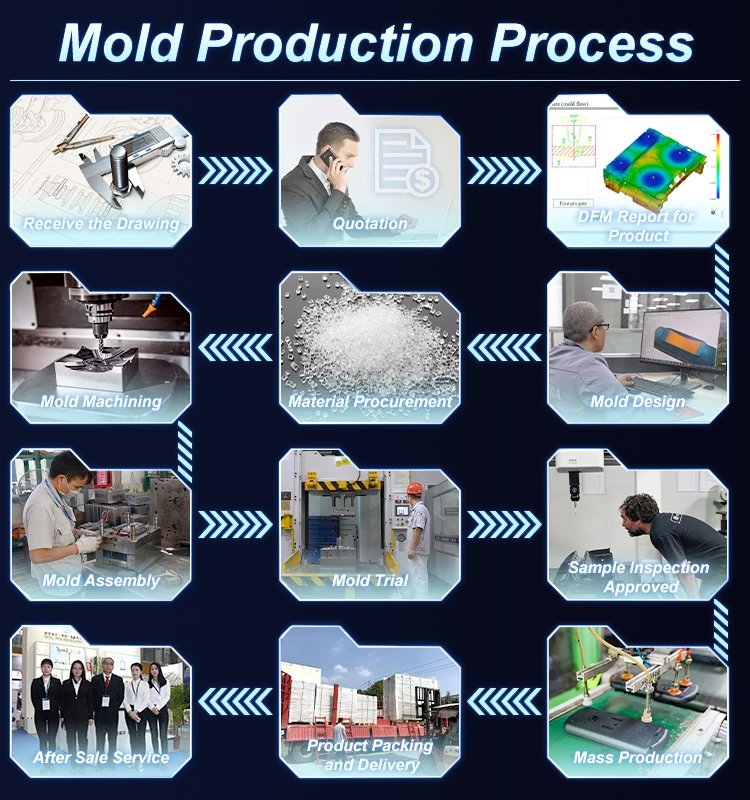

Part IV. Complete Raw Material Procurement Process

Elite Mold has established a comprehensive raw material procurement process to ensure the quality and consistency of our products. This process includes:

- Supplier Vetting: We carefully select and vet our suppliers to ensure they meet our stringent quality standards.

- Quality Control: Rigorous quality control measures are in place to inspect and test raw materials before they are used in production.

- Sustainable Sourcing: We prioritize sustainable sourcing practices to minimize environmental impact and promote responsible manufacturing.

Our thorough procurement process guarantees that we use only the highest quality materials, contributing to the durability and performance of our injection molds.

Part V. Multiple International Standard Certifications

Elite Mold has obtained multiple international standard certifications, demonstrating our commitment to quality, safety, and environmental responsibility. These certifications include:

- ISO 9001: This certification confirms our adherence to quality management systems and continuous improvement practices.

- ISO 14001: Our environmental management systems meet the standards set by this certification, reflecting our commitment to sustainable practices.

- ISO/TS 16949: This certification highlights our capability to meet the stringent quality requirements of the automotive industry.

These certifications provide our clients with confidence in our ability to deliver high-quality products that comply with international standards.

Conclusion

Elite Mold is the ideal choice for your injection mold supplier due to our advanced production equipment, low-cost solutions, skilled team, comprehensive raw material procurement process, and multiple international certifications. As a leading plastic injection mold manufacturer, we are committed to providing exceptional products and services that meet the diverse needs of our clients.