Elite mold is a plastic injection molding company focusing on plastic areas to supply the full one-stop solution of injection molds and injection molded parts for our customers for many years.

As a plastic injection mold manufacturer, Elite mold exports many plastic injection molds and parts to Oceania,America countries and USA, etc. In addition, we have an excellent in-house production capability, up-to-date production facilities, and a unique organizational structure specializing in plastic injection. Our well-trained and motivated employees are our main assets and thus provide for know-how and competence at a high level.

Our mission is to keep our customers successful on all of their key projects. Our business philosophy is to maxim the benefits during the whole process from ideas to real products for our customers in the long term!

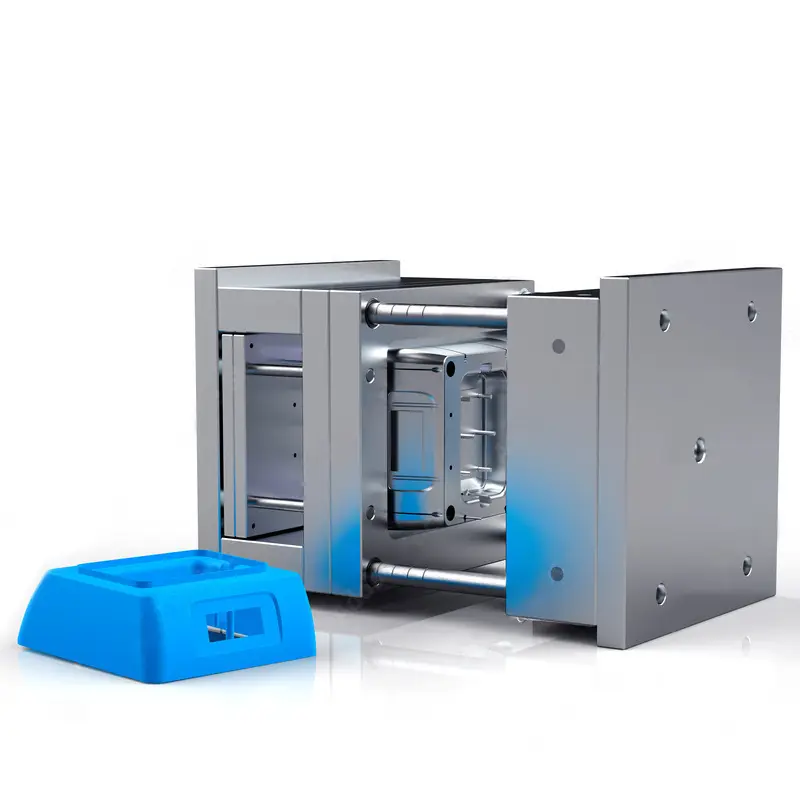

| Shaping Mode | Plastic Injection Mould |

| Place of Origin | Guangdong, China |

| Model Number | customized plastic injection mold mold-G21325 |

| Product Material | Plastic |

| Product | Bearing mold |

| Product Name | Plastic injection mold |

| Mold material | P20/718/738/NAK80/S136 |

| Material | PMMA/ABS/PE/PC/PVC/POMPS/PP/PET/PA |

| Design software | CAD/PROE/UG/3D/DWG/IGS/STEP/PDF/JPG |

| Cavity | Multi Cavity moulds |

| Mould life | 253003shots |

| Runner | Cold Runner. Hot Runner: Yudo |

| Surface treatment | Polish. Etched. Texture |

| Certification | ISO9001:2015 |

| Size |

74 * 54 * 46 OEM/ODM/Customization |

| Packaging Details |

1. injection mold: by pallet or as buyer’s request. 2. injection parts: by bags then export carton, or as buyer’s request. |

| Port | Shenzhen |

| Supply Ability |

20000 Piece/Pieces per Day Please contact the us to check the exact delivery time |

| Samples |

Maximum order quantity: 1000 piece Sample price: $16/piece Please contact us to confirmation |

Custom Injection Molds

aluminum injection molding Material Selection

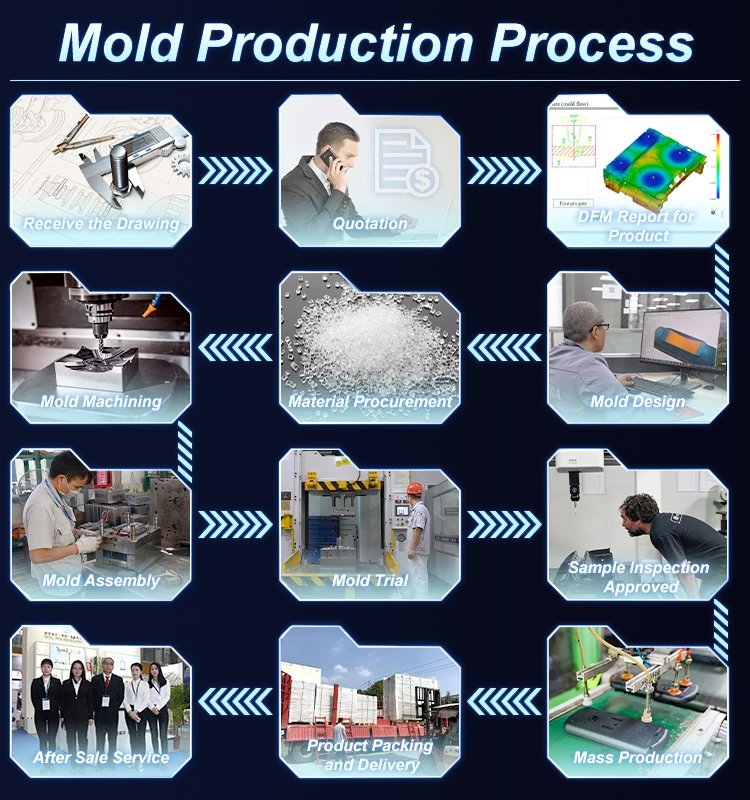

aluminum injection molding Prdduction Process

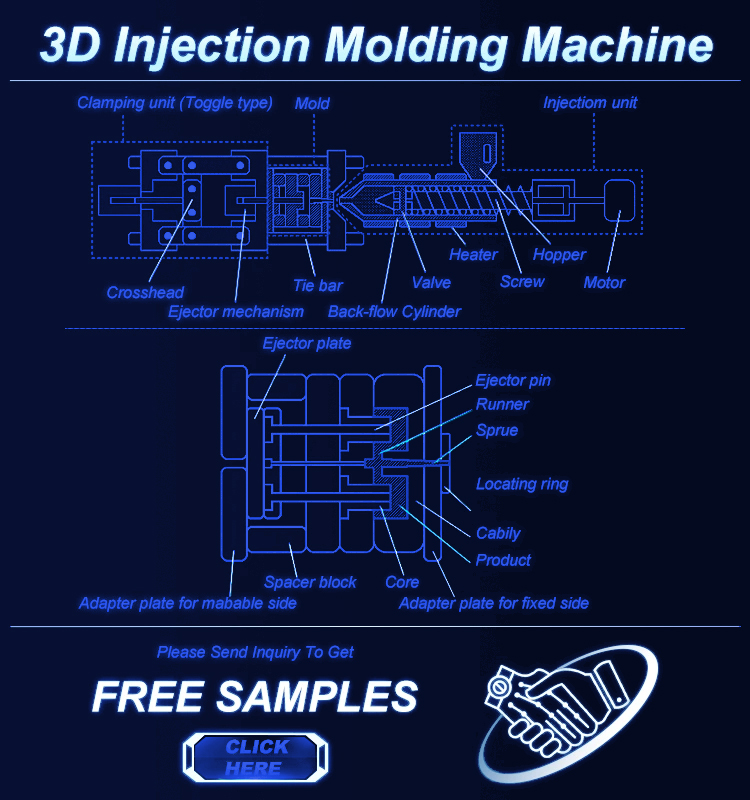

3D Injection Molding Machine

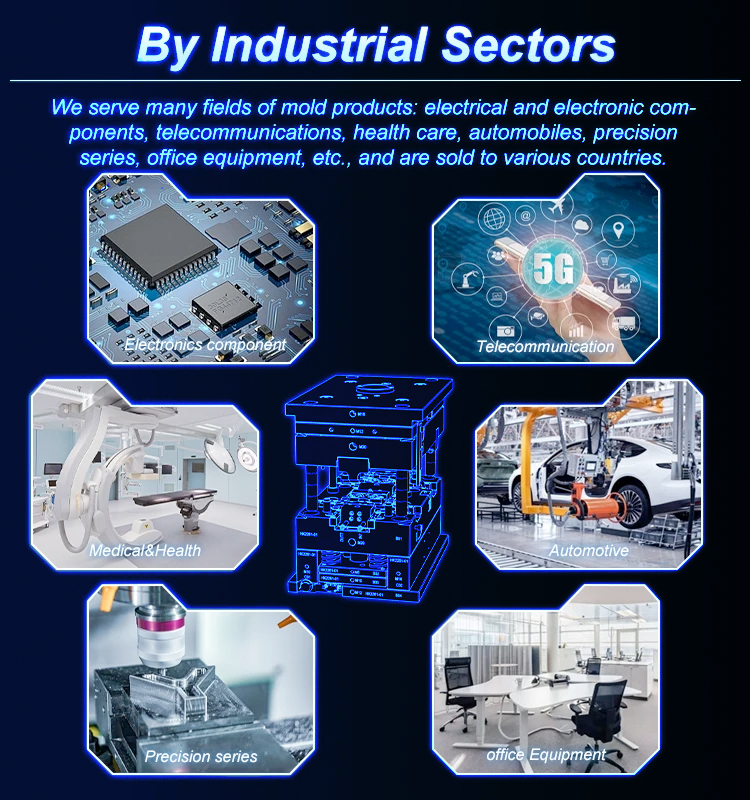

By Industrial Sectors

Elite mold as one of the most professional aluminum injection molding manufacturers has the advantages at:

All our products are strictly according to ISO/SGS regulations, with affordable prices with unparalleled quality.

We take care of our product quality, any defect of the goods, we will take responsibility. You are risk-free.

Big production capacity makes short lead time 7 – 20 days, depending on the complexity of the product.

OEM/ODM service is available.

Low MOQ, we can accept low MOQ as 192 sets, or even less quantity for every single item in big production order.

We have full experience in exporting and project management, to secure your order 100%.

With 15 years of experience in the injection mold industry, we have full experience in customized product development. And we have quite some top-rated products to meet your market requirement.

Full range of plastic window trim molding,injection mold silicone,low volume plastic injection molding,plastic wall trim moulding,custom plastic injection molding and accessories, to meet customer’s different needs.

Tag:plastic insert molding,peek plastic molding plastic molded parts